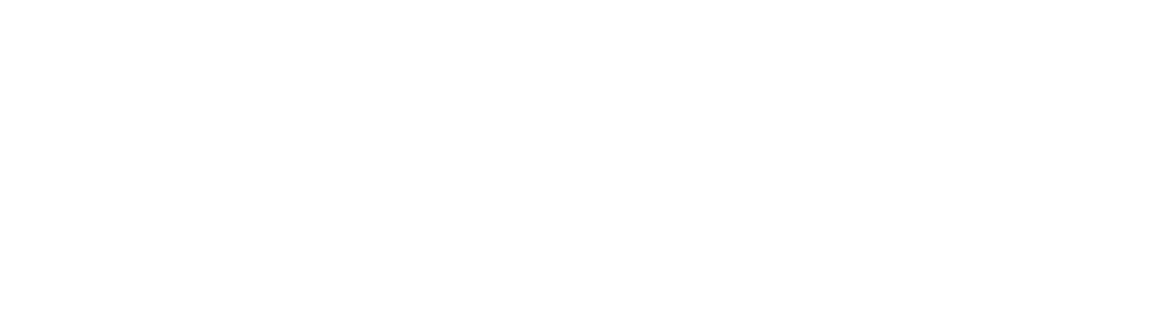

Characteristics of Tin

Tin is a metallic solid with the chemical symbol Sn. Under normal conditions of atmospheric pressure, the element has two allotropic forms depending on the temperature. Below 55.8° F, the alpha form, also known as gray tin has a cubic crystal structure that gives it relatively non-metallic physical properties. At temperatures above 55.8° F, the beta form also known as white tin is predominant and has a tetragonal structure. White metallic tin is dense, conductive, malleable, and relatively corrosion resistant making it very useful as a protective coating on other material surfaces. There are few industrial uses for gray tin, but with small additions of trace metals such as antimony or bismuth, white tin can be prevented from converting back to the alpha allotropic form at temperatures below 55.8° F. Tin is predominantly associated with the mineral cassiterite (Table 1).

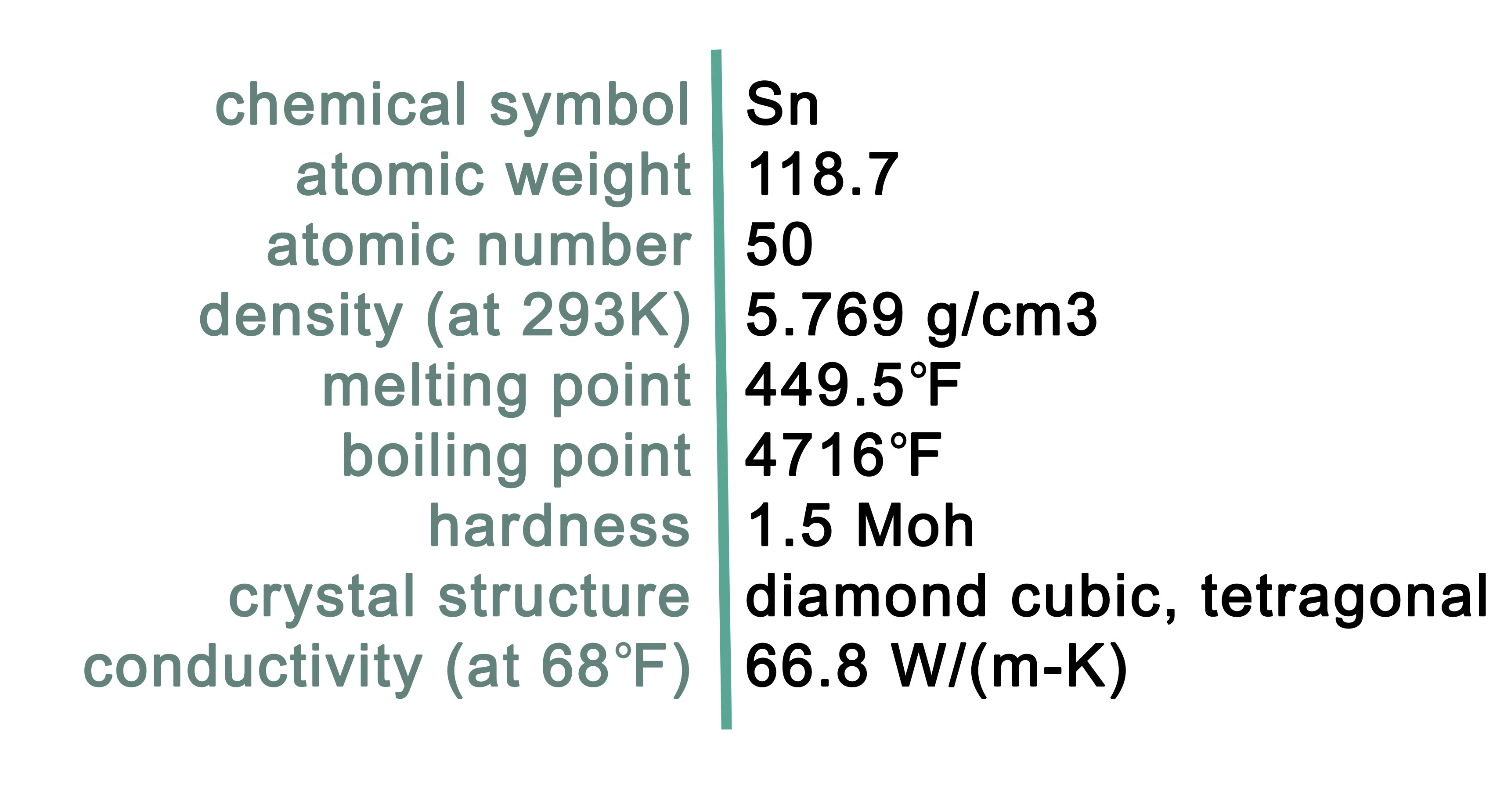

A droplet of molten tin. Courtesy of Jurli, http://images-of-elements.com/tin.php

| Mineral Name | Chemical Formula | Specific Gravity | Sn % |

|---|---|---|---|

| Cassiterite | SnO2 | 6.9 - 7.1 gm/cc | 78.77 |

| Teallite | PbSnS2 | 6.50 gm/cc | 27.61 |

| Stannite | Cu2FeSnS4 | 4.47 gm/cc | 27.61 |

| Cylindrite | Pb3Sn4FeSb2S14 | 5.20 gm/cc | 25.74 |

| Franckeite | Pb4.7Sn2.3FeSb2S14 | 5.63 gm/cc | 13.68 |

| Canfieldite | Ag8SnS6 | 6.31 gm/cc | 10.11 |

Table 1: Minerals containing the element Tin

Uses of Tin

The use of tin in metal alloys dates back as early as the Bronze Age (3,000 BC to 500 AD). Additions of metallic tin to copper produced bronze, which was easier to cast, was more workable, and held a more durable edge compared to copper alone. As an alloy with other metals, tin is used for many agricultural, chemical, and electrical applications. Tin alloyed with niobium is used to produce wire that is superconductive at relatively low temperatures and may soon be utilized in the manufacture of high field strength magnets that consume less energy to operate. Tin also provides resistance to chemical corrosion and is used as a coating on other metal surfaces such as steel in "tin cans". Tin is used for soldering pipes and electrical circuits. Tin salt compounds sprayed onto glass provide an electrically conductive coating for panel lighting and frost-free windshields. Indium-tin-oxide alloys are an important component of flat panel display technologies that are used in a wide range of consumer electronics and defense applications, including computers and mobile devices, medical equipment, cameras, etc. Tin is considered a "critical mineral" in domestic metallurgical applications that serve defense, electronics, and telecommunications technologies (Fortier and others, 2018).

Tin Geology

Elemental tin does not occur in nature. The element is obtained mainly from the mineral cassiterite, which occurs in deposit types associated with two categories of mineralized systems (Table 2). Porphyry Sn systems are large subvolcanic intrusive stocks, often of granitic composition, with complex thermal and chemical gradients. These geologic systems may contain cassiterite and other metallic mineral deposits as disseminations, veins, and hydrothermal alterations including greisens and skarns. Surface weathering and erosion over time exposes the porphyry-related deposits and redistributes heavy minerals like cassiterite in placer system tin deposits. Most of the world's tin production recovers cassiterite from sedimentary placer deposits.

| Mineral System | Deposit Type | Geologic Provinces |

|---|---|---|

| Placer | Cassiterite | Blue Ridge |

| Porphyry Sn (granite-related) | Post-magmatic quartz-sulfide veins in greisen; granodiorite | Blue Ridge |

Table 2: Prospective tin mineral systems, deposit types (Hofstra and Kreiner, 2020), and geologic provinces in Virginia

Tin in Industry

Tin is globally distributed, but relatively rare. Although the U.S. maintains a supply of tin in the National Defense Stockpile, approximately 75 percent of tin is imported from Bolivia, Indonesia, Nigeria, Malaya, Thailand, and Zaire. Minor occurrences within the United States are primarily in Alaska and California.

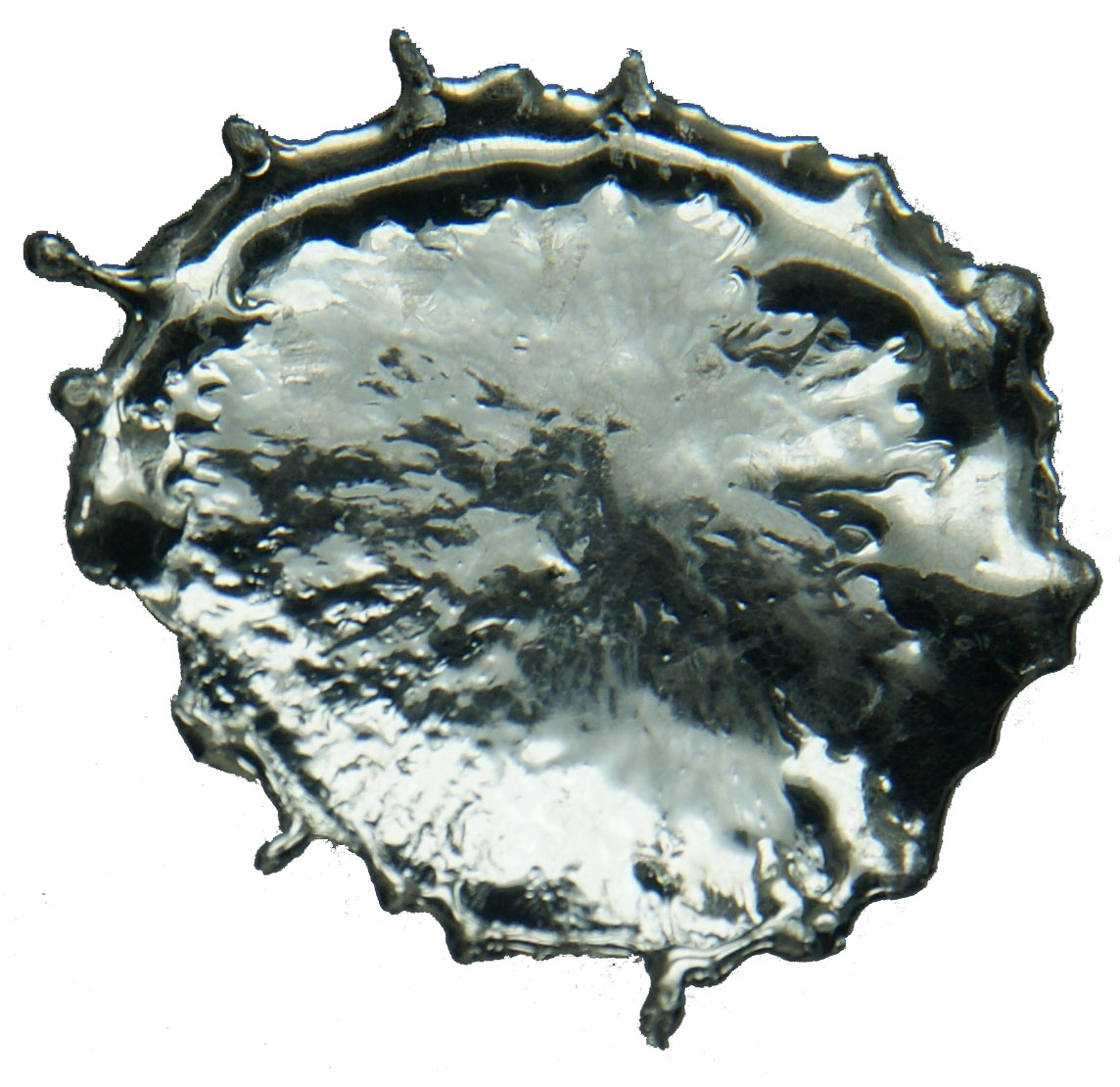

In Virginia, occurrences of the tin-bearing mineral cassiterite were recognized in the vicinity of Irish Creek in Rockbridge County prior to 1846. In that year, a sample from the site was analyzed at nearby Washington College and the presence of both tin and silver were reported (Watson, 1907). However, it was nearly forty years later that mining began in 1884 along Panther Run, a small tributary to Irish Creek. Mining was conducted intermittently during the periods of 1884-1886, 1890-1892, and 1918-1919. Total production in the district has been estimated at 3,200 tons of ore with an average grade of about 1 percent SnO2, yielding approximately 330 tons of tin (Good, 1991). During later exploration of the deposit, a significantly lower tin content of 0.49 percent was reported (Adair, 1942).

The Irish Creek Mining District of Virginia. Modified from Koschmann and others, 1942.

The tin-bearing cassiterite at Irish Creek occurs mainly in gray quartz veins bordering greisen-altered granodiorite with minor disseminations within the greisen zones (Koschmann and others, 1942). The granodiorite intrudes clinopyroxene-hypersthene-hornblende granulite gneiss originally mapped as part of the Pedlar Formation. The deposits contain a number of other minerals including arsenopyrite, pyrite, hematite, pyrrhotite, galena, beryl, scheelite, wolframite, sphalerite, siderite, and apatite.

Selected References:

Adair, 1942, Report on the Irish tin prospect - unpublished Bethlehem Steel interoffice memorandum, in French, B.B., 1956, interoffice memorandum of 9/19/56 of Atlantic Lumber Company, Boston, Massachusetts summarizing drilling and assays by S. Lake in 1942 investigation by Bethlehem Steel Company geologic staff: Virginia Division of Geology and Mineral Resources economic section files.

Bloomer, R.O., and Werner, H.J., 1955, Geology of the Blue Ridge in central Virginia: Geological Society of America Bulletin v. 66, p. 579-606.

Carter, M.W., Crider, E.A., Southworth, C.S., and Aleinikoff, J.N., 2016, Detailed geologic mapping geodatabase for the Blue Ridge Parkway in Virginia with station point photographs: U.S. Geological Survey data release.

Carter, M.W., Southworth, C.S., Tollo, R.P., Merschat, A.J., Wagner, S., Lazor, A., and Aleinikoff, J.N., 2017, Geology along the Blue Ridge Parkway in Virginia, in Bailey, C.M. and Jaye, S., From the Blue Ridge to the beach: Geological field excursions across Virginia, The Geological Society of America, v. 47.

Ferguson, H. G., 1918, Tin deposits near Irish Creek, Virginia: Virginia Geological Survey Bulletin XV-A, 19 p.

Fortier, S.M., Nassar, N.T., Lederer, G.W., Brainard, J., Gambogi, J., and McCullough, E.A., 2018, Draft Critical Mineral List - Summary of Methodology and Background Information - U.S. Geological Survey Technical Input Document in Response to Secretarial Order No. 3359: U.S. Geological Survey Open-File Report 2018-1021, 15 p.

Good, R. S., 1991, Gold mineralization, and tin, base metals, and thorium anomalies at Yankee Horse Ridge, Irish Creek tin area, Rockbridge County, Virginia: Virginia Division of Mineral Resources Publication 112, 41 p.

Hofstra, A.H., and Kreiner, D.C., 2020, Systems-Deposits-Commodities-Critical Minerals Table for the Earth Mapping Resources Initiative: U.S. Geological Survey Open-File Report 2020-1042.

Koschmann, A.H., Glass, J.J., and Vhay, J.S., 1942, Tin Deposits of Irish Creek: U.S. Geological Survey Bulletin 936-K. p. 271-296.

Watson, T.L., 1907, Mineral Resources of Virginia: The Virginia Jamestown Exposition Commission, J. P. Bell Company, Lynchburg, Virginia, 618 p.

.jpg)